The Electronic Workplace

Out in the northern Kentucky hills, not far from Cincinnati, an eerie minuet of machines strikes up every night on the green slab floor of a factory. It begins late in the evening, during the third shift at Mazak Corp.'s new machine-tool plant in Florence, and it plays until sunrise.

During the first shift at the plant, in the morning and early afternoon, two workers watch over a series of giant yellow machining centers, machines that bore a complex pattern of holes into iron castings. So automated is the system that rarely do the men have to touch the machines they direct. When those workers go home, at the start of the second shift, they are replaced by two more.

But eight hours later, when the third shift starts at midnight, the dance of the machines begins. The workers line up a shift's worth of castings for the machining centers, turn out the lights and go home. The machining centers, controlled only by the factory's computers, bore away in the dark at the five-ton cast-iron pieces; the wail of metal on metal and the clanking of tools changing automatically are the only sounds in the night. Around them, robot carriers -heavy, computer-guided carts -quietly load the castings on the machines and haul them off when they're done. When the first shift returns in the morning and turns on the lights, the finished castings are stacked on one side, ready for shipment to the assembly line.

It is a Japanese-owned factory, but German workers have the best term for the kind of automation that runs the Mazak plant at night. They call it die Geisterschicht. The ghost shift.

This is factory automation, electronically reborn in the 1980s, and the Mazak plant is one of a dozen or more plants around the country where computers have taken on essential -and, sometimes, central -roles in managing the factory. Mazak is different in that it has that ghostly, unmanned third shift, but others are installing automation systems that seem, in their own way, just as spectral.

What seems ghost-like in these newly automated factories are the computers that run them. Even 10 years ago, computers were big, expensive, heat-generating machines that were typically purchased by big businesses and stuck in glassed-in basement rooms. There they labored away at only the biggest and most tedious of tasks -managing a company's payroll, say, or taking care of the billings.

But with the revolutionary development of the microprocessor -the computer-on-a-chip -in 1971, the world of computer technology took a quantum leap downward, both in size and price. In the years since, the microprocessor has spawned entire generations of tiny, cheap computers that perform like room-sized models of the 1960s. So tiny and cheap that, for the price of a used car, an accountant can buy a sophisticated machine that will sit on his lap and answer questions about a company's financial fitness. So tiny and cheap, even, that a factory can install computer technology in its machines, as Mazak has done, so they glide about in the dark as if they had some kind of ghostly intelligence.

The result is that cheap computer power, like cheap steam power and cheap electrical power before it, is bringing on a new Industrial Revolution, one that promises, before it is done, to change the way work is done in America. It is clear already what electronics is doing to work in factories. Computers are setting production schedules, running the machines and even checking their own work to make sure it is machine-perfect. "The worker," notes Melvin Kranzberg, professor of the history of technology at Georgia Tech, "is becoming a dial watcher, an observer, not a machine operator." And since factories don't need many observers, computers could end up being the saviors of industrial America, even as they take away most of industrial America's jobs.

The workplace is going high-tech at a fast pace. Businesses, from grocery stores to multinational manufacturers, spent at least $47 billion last year to bring computers to the very heart of their enterprises, an eye-opening sum in one of the worst years for business in half a century. Manufacturing companies alone are estimated to have spent $26 billion on the latest in factory automation systems and services. Offices and service companies chipped in at least $21 billion more on electronic office equipment, from word processors and smart copiers to advanced phone systems and desktop computers.

And the flood of electronics is just beginning. Ten years from now, factories will be spending four times as much as they do now -or about $100 billion a year -on computer-managed automation systems, experts believe. More startling will be the growth of computers themselves. There are five million computers on the face of the earth today; in four years, there will be 25 million, according to International Data Corp., which keeps statistics on the computer industry. And by 1990, 40 to 50 percent of all American workers will use computers in their work, adds Arthur D. Little Inc., the management consulting firm.

Behind the scenes, cheap computer power is forcing some of the most wrenching changes in work since electricity, telephones and typewriters swept through factories and offices 100 years ago. A few glimpses backstage at the electronic workplace:

At Southeast Bank in Miami, Quick & Easy computer-automated teller machines are the rage among the bank's management. The best located ones carry out 8,000 to 10,000 transactions a month. They take deposits, hand out cash, check on balances, even shift money from one account to another, all at the stroke of a few buttons on a keyboard. So happy is Southeast with its 130 machines that it is about to multiply that number several times by joining a statewide network of automated teller machines. When the switch is thrown on the new network this fall, Southeast's customers can take a Quick & Easy card to nearly any bank machine in the state, whether it belongs to Southeast or a competitor, and get cash on the spot. But what really excites bank executives is the machines' staggering cost efficiency. A transaction on a computer teller, surveys show, costs the bank about half what it does when a customer passes a check through the window to a human teller.

For that simple economic reason, the number of teller machines nationwide doubles every two years. There are now about 30,000 of the silent electronic tellers around the country.

At General Motors Corp.'s technical center in Warren, Mich., automobile designers hunch over computer terminals, waiting for the computer to review their work. When they've finished creating a new part -say, a crankshaft -the designers ask the computer to look at the geometry used to build the part and to subject the part to some tests. The computer tells them where the likely stress points will be in the crankshaft, whether it is in balance, and how it will bear up in actual use. Too many problems and the part never makes it further than a brief run through the computer's memory banks.

Computer-aided design, as it is called, was pioneered by the auto and aerospace industries. Now, thanks to cheap computer power, it is spreading rapidly to other businesses from electronics companies to architects.

At Publix supermarkets around Florida, store managers reorder their shelf stock with the help of a hand-held computer. As they walk along the aisles, the managers simply run a small electronic wand from the computer over the product codes of the items they wish to order. For a double order, they wave the wand twice. When they are done, they plug the computer into a special phone outlet. Publix's computer in Lakeland sweeps through the phone lines of all 267 stores and picks up the orders. Later, the computer forwards the order to the Publix warehouses.

The tiny reordering computers -some as small as cigarette packs -are as common to retailing today as weekend specials.

At John Deere & Co.'s tractor assembly plant in Waterloo, Iowa, a bank of computers schedules materials and parts and draws up work assignments for employees to meet the day's production run. So ensconced have the computers become in the management of the plant that they even control, on their own, the giant overhead conveyor systems that move large parts from the storage areas to the assembly lines. Having decided how the assembly lines will run that day, the computers make sure the right parts get to the right point on the line at exactly the moment they are needed.

The Deere system is so advanced, it won an award two years ago from a manufacturing engineers association.

$8 Million Cell

These are not casual changes in work. Most offices and factories and stores are loathe to change work routines that have been built up over generations of employees. Nor are the changes necessarily cheap, even by corporation's standards. While the cost of computer power is dropping rapidly -every 2 1/2 years, the cost of computing is cut in half -the other ingredients of factory automation, the machining centers, the mills, the lathes and so on, are still chillingly expensive. Cincinnati Wilacron Inc. recently sold a single computer-driven flexible machining cell to the Vought Corp. of Dallas for $8 million. Vought spent $2 million more to install it. The cell will be used to make fuselage sections for the Air Force's new B-1 bomber. It is all but unmanned. Unless there is a problem on the factory floor, human workers tending the cell will remain inside an air-conditioned computer control booth, where they will monitor instruments at their finger tips and watch through the window as robot carriers scurry amongst their machine cousins.

What drives companies to shell out that kind of money for computer automation is a revivalist spirit that is sweeping American industrial circles. It began during the last, bitter recession -the one that ended late last year-and followed a decade during which the Japanese overran one strategic manufacturing market after another with a bewildering display of industrial virility. During the recession, American industrialists came to two conclusions: The old ways of manufacturing weren't working, and electronics held the answer to changing the old ways.

One of the chief prophets of the change-it-or-lose-it religion is James A. Baker, an executive vice president at General Electric Co. A scholarly looking man who wears large, dark-frame glasses, Baker lectures audiences at industrial meetings and conventions that American manufacturers are faced with three stark choices: They can "automate, emigrate or evaporate," meaning companies must either invest in automation, move their plants to low-wage countries or watch themselves be strangled to death by their competition, foreign or domestic.

"The arithmetic is simple and devastating," Baker explains. Company A refuses to invest in automation, trusting the old ways to continue the good times. Company B, its competitor, takes the automation plunge. Company A's productivity, rises at about two percent a year, the national average. Company B's productivity, boosted by modest automation starts climbing by six percent a year. Inside 10 years, says Baker, Company B can make its products 34 percent cheaper than Company A can. "And at that point," he adds solemnly, "you can probably kiss Company A goodbye."

One of the companies that shares Baker's vision -and his faith in the inevitability of mathematics -is General Motors, which has felt the hot breath of Japanese competitors who build their cars with more automation and fewer workers. GM's answer is massive automation. Three years ago, GM had 275 robots in its plants. Today it has 2,300 in place or in some phase of installation. By 1990, GM predicts, it will have 14,000 computer-controlled robots, laboring at everything from welding and painting to assembling dashboards and loading other machines. Some GM executives think the official figure is too low. They think the company will actually have far more than 14,000 robots at work by the end of the decade.

Baker's own company, General Electric, is no laggard in automation either. Over the past two years, it has pumped $1 billion into equipping old plants with the latest in automation systems. And there's more money in the till for automation. At its once-dowdy Erie, Penn., locomotive factory, for instance, GE has promised to spend $316 million by 1986 to turn the plant into a model of industrial efficiency. When the reworking is done, the Erie complex will be able to turn out a third more locomotives than it can now and will be able to do so with only 12 percent more floor space -and only 10 percent more workers.

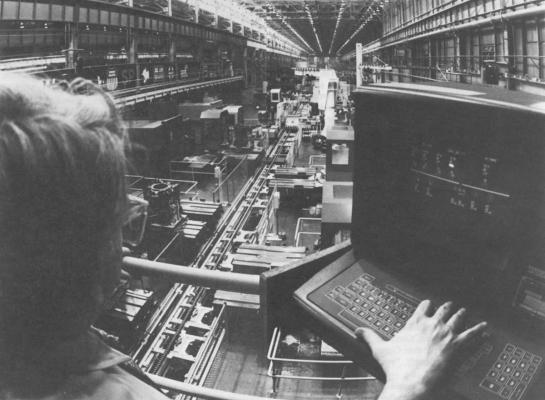

A part of the Erie plant's future is already in place. In one building, GE has installed $16 million in computer-controlled equipment to automate the construction of traction motor frames. In the past, it took 68 machine operators three weeks to put together a single 2,500pound motor frame. Today, five workers, including the computer operator in the cubicle overlooking the factory floor, turn out a frame a day -a stunning 240 percent leap in productivity. "And the frames we make here are better than we've ever made," adds Robert D. Melin, the Erie plant's manager of technology development, as he stood on a catwalk over the new motor frame section. Below, a single worker could be seen, casually adjusting the tools on the mammoth horizontal boring machine.

Up to now, cheap computer power's Industrial Revolution has been mostly that -industrial. It has had only a marginal effect on office work, where roughly 65 percent of American workers make their living. The most visible contribution of electronics to the office has been the word processor, which is fast replacing the electric typewriter as standard secretarial equipment. But word processors -which are basically computers that help compose and print letters -are usually the beginning and end of office automation, even in the biggest companies. One survey found, in fact, that only about 60 of the nation's top 1,000 industrial corporations have outfitted their offices with the most advanced electronic equipment.

Why the slow progress in office automation? There is a scattering of reasons. Lower-level office workers aren't paid as well as their counterparts on the factory floor, so there is less incentive for offices to automate. The threat from a more automated competitor, like the Japanese, is felt less keenly in the office than it is in the factory. Also, there's no tradition of automation in the office as there is in the plant, so office managers tend to view change more skeptically than do shop foremen.

More important, office automation, for all the breezy television commercials inviting companies to race boldly into the future, isn't quite all there yet. There are bits and pieces of it -word processors, desktop computers, advanced copiers and computer-managed phone networks -but no one has yet put together a practical office-automation system that does it all. As a result, says Sid Rhoades, senior regional marketing representative in Atlanta for IBM, many companies are looking at computer automation for their office operations, but few are buying it. "They're getting very interested in it," he explained, "but since it is not a proven package,' in quotes, that does everything -we're still working on that -people are moving cautiously."

But automation will come to the office, experts say. And when it does, they add, it will probably cause a greater upheaval in work there than it has in the factory.

There are two reasons for the inevitable marriage of computers and office work. First, that is where the people are. Even at General Electric, one of the nation's premier industrial companies and maker of everything from light bulbs to nuclear turbines, only 40 percent of the company's workers are actually involved in production. The rest -accountants, clerks, executives, secretaries -are paper-shufflers. Second, among the labor sectors, office workers have lagged the most in terms of productivity growth. During the 1970s, factory productivity grew by 90 percent. Office productivity during the same period, grew just 4 percent. With those kinds of numbers -and problems -in their white-collar ranks, observers believe, companies will be forced into office automation before long.

When they are, the anguish of automation will probably be far greater in the office than it has been on the shop floor. More than factories, offices have grown into bewildering mazes of inefficiency over the years. Before computers can take over part of the work, those mazes have to be dismantled, and clear, precise pathways of information built in their stead so the machines can understand them. Just how daunting that task will be was shown several years ago, when Intel Corp. in Santa Clara, Calif., decided to take a look at its choking office bureaucracy. What Intel managers found was appalling. Ordering the simplest office supplies -pencils, paper and the like -required 12 pieces of paper and 95 separate administrative steps. To hire someone, the company took 364 bureaucratic steps. Much angst and many flattened toes later, Intel had made some sense of its own administration. Ordering a pencil now takes one piece of paper and eight steps. Hiring a new worker can be done in 250 steps. Intel officials say their program -which involved thoroughly redesigning the flow of information through its offices -boosted white-collar productivity by 30 percent.

The irony is that Intel is no sooty, smokestack company, its management encrusted with memories of the way business used to be. In fact, Intel is a relatively young company, a high-technology manufacturer that is at the cutting edge of the new Industrial Revolution. Its best-known product is a tiny, cheap computer device it developed in 1971. It is called the microprocessor.